BOXmaker MULTI

Unparalleled flexibility with manual tooling for diverse box formats and parallel production setups.

Unparalleled flexibility with manual tooling for diverse box formats and parallel production setups.

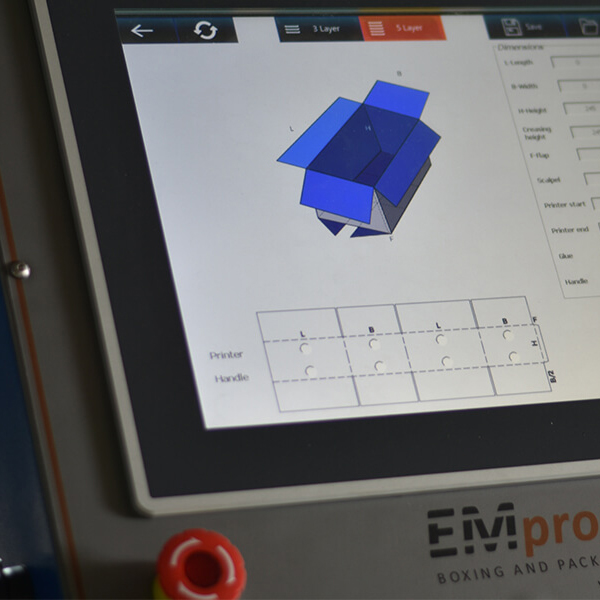

Manual interface with simple calibration and mechanical adjustment for each production setup. Provides flexible format selection, repeatable alignment, and quick changeovers between box types.

Three 500 mm segmented knives (100 mm segments) ensure excellent flexibility in slot width and box design. Built from durable steel alloy, suitable for processing single, double, and triple-wall boards.

Four creasing wheels enable accurate folding across multiple box types. Each wheel is manually adjustable, ensuring consistent scoring quality for various production formats.

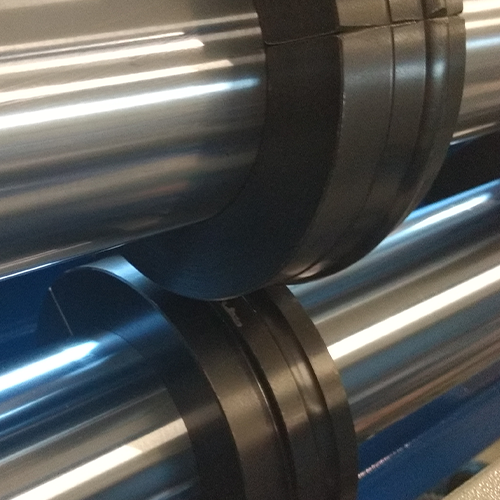

Two circular knives provide precise longitudinal cutting and edge reformatting. A quick-change system allows easy swapping for different widths and designs.

Manual cross-cutting system for trimming, flap cutting, and separating multiple boxes from a single sheet. Engineered for high accuracy and minimal material waste.

Single-color flexographic printing unit (150 × 470 mm or 300 × 470 mm). Ideal for logistics markings and branding, with optional installation for flexible production requirements.

Cold-glue application system for one-pass completion. Operates with one or two nozzles, ensuring reliable bonding even in multi-box production setups.

Manual die-cut press for handholes and custom shapes. Configurable with one or two tools, depending on production requirements and output needs.

| Corrugated Board Type | single, double, and triple wall |

| Cardboar Thickness | up to 10mm |

| Cardboard Density Range | up to 1000g/m2 |

| Max. Board Size | 2400mm width x 7000mm lenght |

| Min. Board Size | 200mm width x 800mm length |

| Production Capacity | up to 1200 boxes per hour (FEFCO 200) |

| Slotting Knife | 3 x 500mm segmented (in 100mm segments) |

| Distance between slotting knives | 0mm – 2200mm |

| Width Slotting Knife | 8mm |

| Vertical Cutting Knife | 2 x circular knife |

| Soring/Creasing Wheel | 4 x creasing wheels |

| Cross Cutting Knife | 1 |

| Power supply | 6.1kW |

| Air Pressure | 6-8 bar |

| Dimension | 3400mm x 2400mm x 2200mm |

| Gross Weight | 4500kg |

| Automatic Paper Feeding | NO |

| Handhole on Box Sides | YES 120mm x 160mm |

| Printing module | with or without |

| Printing unite size | 150/300mm x 870mm |

| Gluing module | with or without |

| Die-cut | none, one or two |

BOXmaker MULTI is built for manufacturers who demand versatility above all else. With manual tooling and customizable setups, it can produce 2, 4, or even 6 boxes from a single sheet — making it the ideal solution for variable orders and short-run production.

Its sturdy mechanical system ensures consistent precision across all box formats while keeping operation and maintenance simple. Designed for full operator control, the MULTI delivers professional-grade results without the need for automated adjustment systems.

As part of EMproject89’s boxmaking machine portfolio, the MULTI combines flexibility, precision, and durability in one compact design. It supports a wide range of FEFCO codes and custom sizes, allowing manufacturers to scale production easily as their needs evolve.

With its efficient power usage and robust construction, the MULTI stands out as a dependable investment for businesses seeking manual precision and multi-format adaptability at an accessible cost.

With built-in online connectivity for quick issue resolution and adaptable tooling for customer-specific production, the machine processes a wide range of corrugated materials — including E, B, C, A, D, EB, EC, BC, AB, and AC board types — in both flute directions.

It can produce 2, 4, or 6 boxes from one board, allowing highly adaptable, short-run, and multi-format manufacturing.

The MULTI can handle over 80 FEFCO codes in one pass, plus a variety of custom designs through manual adjustment.

It supports single, double, and triple-wall boards up to 10 mm thick and 1000 g/m² density.

All adjustments are performed manually, giving operators full control and flexibility over every step of the production process.

The machine can be configured with optional flexo printing, gluing, and die-cut units for complete one-pass box finishing.

The MULTI operates efficiently with a power supply of 6.1 kW and air pressure between 6 and 8 bar.

The circular knife tool serves the purpose of cutting off surplus cardboard on the sides. The scalpel tools are used for cutting the glue flaps or excess cardboard along the length, as well as allowing for more variations of boxes to be made. FEFCO 204 box production is an example of usage of this module. The machine contains 2 pairs of circular knives knifes and one pair of scalpel tools, all manually set-up with the help of the integrated measuring tape.